Three powerful words define an integrated global automotive services organization with a focus on creating a rewarding career and better life for employees, serving customers with dedication and giving back to the communities in which we live and work.

-

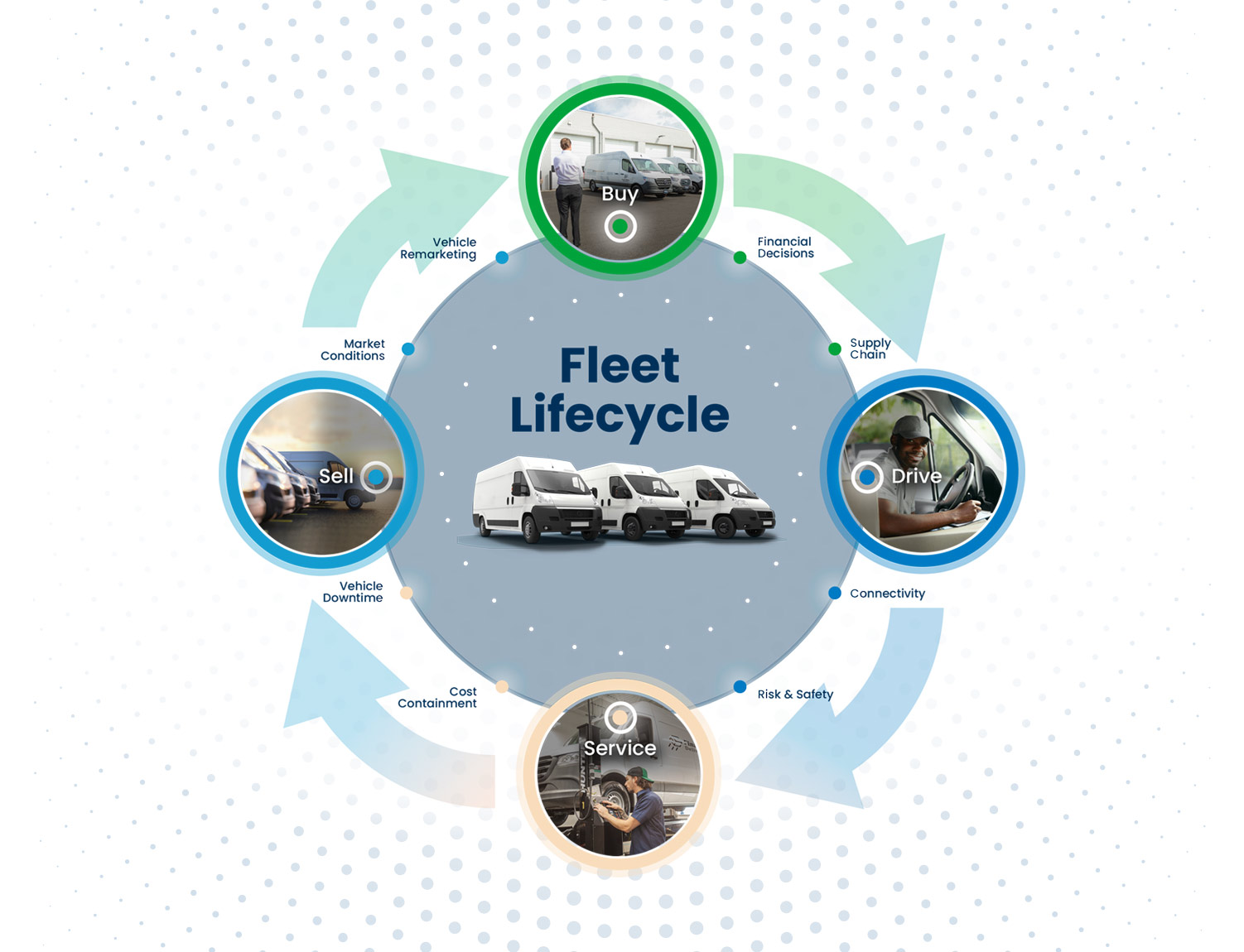

What We DoFrom fleet management and productivity solutions to upfitting, fabrication, and insurance, Holman has the integrated automotive services expertise to keep your business moving.OVERVIEW

-

SolutionsWith a strategic solution that works for you and your business, you can unlock revenue-generating opportunities and begin managing your fleet as an investment.OverviewSolutions by IndustryHolman's fleet expertise covers nearly every vertical industry. No matter your field, we can meet your fleet challenges head on.Solutions by IndustryPersonalized SolutionsEvery company has its own unique set of challenges and considerations when it comes to fleet management. Holman offers customizable solutions to fit your needs.Build Your Own

-

ResourcesWe have a lot to share. Browse our resources library for current insights, data, strategies, and success stories from our own experts in their respective fields.Overview

-

About UsWhen Holman was founded in 1924, we set something positive in motion. Our consistent focus on people and our commitment to integrity make us who we are today.Overview

Join Our TeamWe’re not just in the automotive business, we’re in the people business. Join us for the ride.Browse Careers

Join Our TeamWe’re not just in the automotive business, we’re in the people business. Join us for the ride.Browse Careers